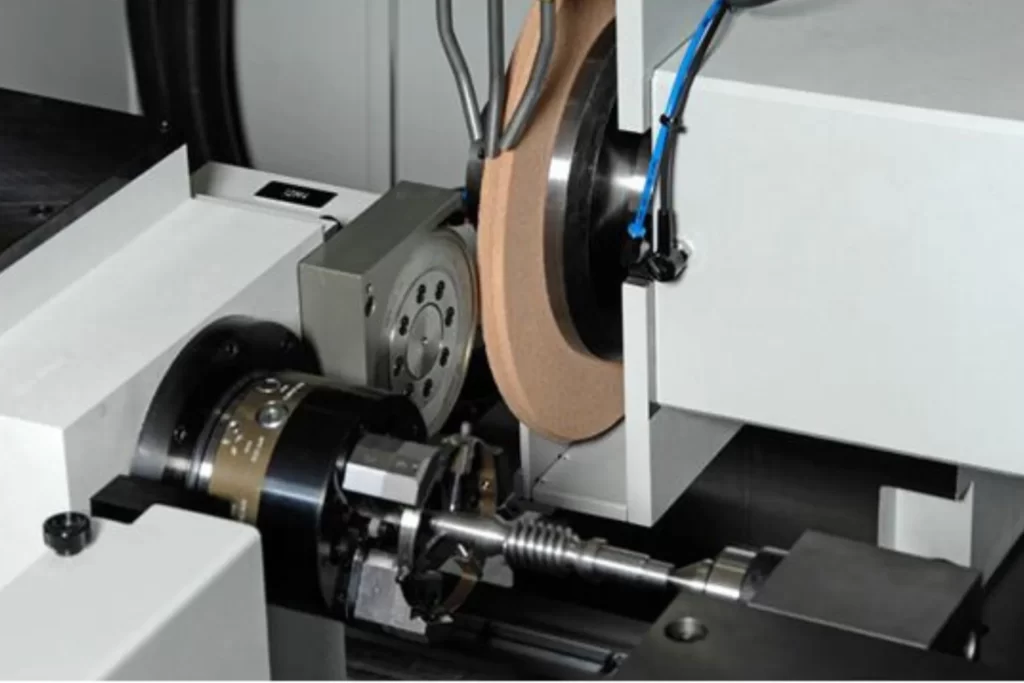

Worm grinder TC-7720

Worm grinding is a specialized grinding process used to create complex and accurate worm gears, which are often found in various mechanical applications such as power transmission, steering systems, and machine tools. The process involves the use of a grinding wheel specially designed to match the profile of the worm gear teeth.

Worm grinding is a versatile process that allows for the production of complex worm gears with high precision and accuracy. It is commonly used in industries such as automotive, aerospace, and power transmission, where reliability and performance are critical.

Worm grinder TC-7720

- TC-7720 CNC Worm Profile Grinder adopts the latest grinding concept and novel on-line grinding wheel dressing programme, which can grind all kinds of worm gears, screws and so on.

- Range of grindable thread diameters:5mm-200mm

- Maximum length of workpiece:450mm

- Module of grindable worm:0.5M-6M

- Grinding wheel spindle angle adjustment range-45°-45°

- 50HZ/380±10%

Key Features and Benefits

Automation and High Efficiency:

Worm grinder adopts advanced automatic control technology, realizing the automation of the whole grinding process. Operators only need to set machining parameters, and the equipment can automatically complete the grinding task, greatly improving production efficiency.

High Precision and Stability

Worm grinder adopts high-precision guide rails, lead screws, and servo motors, as well as advanced control algorithms, to ensure grinding precision and stability. The processed worm gear tooth surface has high precision, low surface roughness, and good meshing performance.

Strong Flexibility

Worm grinder has strong flexibility and can process worms of different specifications and shapes. By changing the grinding wheel and guide wheel, various types of worm grinding can be realized.

Simple Operation and Convenient Maintenance

Worm grinder is easy to operate and maintain. Operators can skillfully operate the equipment. The equipment adopts a modular design, which is easy to maintain and replace parts.

Safe and Reliable

Worm grinder adopts a complete safety protection system to ensure the safety of operators and equipment. The equipment has functions such as overload protection and overheating protection to avoid equipment damage and accidents.

Worm Grinder Technical Specifications

Maximum mounting diameter: 300mm

Maximum centre distance: 500mm

Maximum grindable thread diameter: 200mm

Minimum grindable thread diameter: 5mm

Maximum length of grindable workpiece: 450mm

Worm module: 0.5-6M

Angle adjustment range of grinding wheel spindle: – 45°~45°.

Number of grindable threads: Any

Maximum linear speed of grinding wheel: 45m/s

Outer diameter×inner diameter: φ400×φ127mm

Thickness: 10, 16, 20, 25mm

Worm Grinder Technical Descriptions

TC-7720 CNC thread grinding machine is equipped with FAGOR CNC system to achieve four-axis, Triple linkage control.

The rotary motion of the workpiece, the lateral motion of the table, the rotary motion of the screw angle and linear motion, and the linear motion of the diamond roller are all controlled by YASKAWA servo motors. The rotary motion of workpiece, transverse motion of table, rotary motion and linear motion of helix lifting angle, and linear motion of diamond roller are all driven by YASKAWA servo motors from Japan.

The diamond roller is controlled by the electric spindle. The rotary motion of the grinding wheel spindle is driven by internal AC permanent magnet synchronous motor. The rotary motion of the grinding wheel spindle is driven by an internal AC permanent magnet synchronous motor.

The rotary motion of the workpiece, the transverse motion of the table, the rotary motion of the helix angle and the linear motion of the diamond roller are all driven by YASKAWA servo motors. The rotary motion of the workpiece, the lateral motion of the table, the rotary motion and the linear motion of the helical lift angle, and the linear motion of the diamond wheel are all equipped with Spanish Fagor scales to achieve full closed-loop control.

The X-axis and Z-axis linkage interpolation realises the dressing of various grinding wheels’ truncated shapes, and the dressing amount of grinding wheels can be adjusted by X-axis and Z-axis linkage interpolation. The dressing amount of the grinding wheel can be automatically compensated by the longitudinal movement of X-axis.

Innovative Technology in Worm Grinding

The world of worm grinding has witnessed a transformative shift with the advent of innovative technologies.

These advancements have revolutionized the manufacturing process, enabling the production of worm gears with unprecedented precision and efficiency.

At the forefront of this revolution are advanced grinding machines equipped with state-of-the-art control systems, sophisticated software, and intelligent automation features.

These machines utilize high-speed spindles, precision tooling, and real-time monitoring systems to deliver exceptional accuracy and repeatability.

Worm Grinding: Achieving High-Precision and Accuracy

Worm grinding is a specialized manufacturing process that utilizes a grinding wheel to create complex and precise worm gears.

This process involves removing material from the worm gear blank to form the desired tooth profile.

Due to the intricate nature of worm gears, achieving high precision and accuracy is crucial for ensuring proper meshing and optimal performance in various mechanical applications.

Worm grinding excels in this regard, as it allows for the production of worm gears with tight tolerances and exceptional surface finishes.

ONMY Machines to Start Your Business

Have a look at how some of our clients perceive our goods and services: