Thread whirling machines

- A thread whirling machine is a specialized type of machine tool used to produce threads, grooves, or other profiles on cylindrical or conical workpieces.

- Unlike traditional milling or turning machines, the cutting tool in a thread whirling machine rotates around the workpiece while being fed axially. This allows for incredibly precise machining at higher speeds.

- The workpiece diameter is 12mm

- The machining length is 100mm.

- The total length is 180mm.

- Helical angle range:-3°-20°

The workpiece size support range is extensive, covering diameters from 10-250mm and lengths from 10-700mm.

The workpiece size support range is extensive, covering diameters from 10-300mm and lengths from 10-700mm.

The workpiece size support range is extensive, covering diameters from 10-400mm and lengths from 10-2700mm.

How does thread whirling machine work?

- Workpiece setup: The workpiece is securely clamped in a chuck or between centers.

- Cutter head: The cutter head contains multiple carbide inserts arranged in a ring. The design of these inserts allows the whirling machine to form threads, grooves, and other profiles.

- Rotation: The workpiece is rotated, and the cutter head rotates simultaneously in the opposite direction at very high speed.

- Axial feed: The cutter head is gradually fed along the axis of the workpiece, carving out the desired shape.

Advantages of our thread whirling machines

The spindle motor is a direct-connected structure, which can output more torque, better mute effect, higher transmission efficiency and more stable transmission.

The vast majority of the market choose the belt connection structure, just to reduce costs.

Schneider wiring power supply, quality is guaranteed.

The overall line layout is scientific, reasonable and clear, and each line and switch is labeled using labels, so that the factory can quickly check and solve the problem once the machine has a problem.

System optionality. You can choose from Siemens, GSK, Fanuc, Mitsubishi systems depending on your needs.

All the accessories will be adjusted according to the system, there will not be the case of configuring Siemens system but installing other motors. We only for the stability of the machine.

Processing caseⅠ

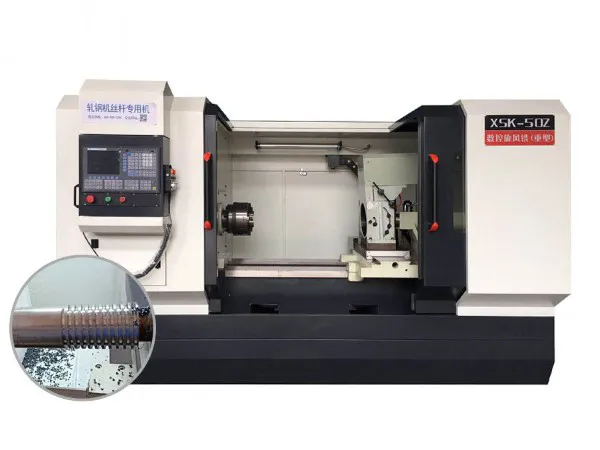

- Thread whirling machine model:XSK-50

- Reducer worm M9

- Z1=2

- O.D. 80

- Helix angle γ=12°40′

- Machining time for a single part:15 minutes

- Roughness of tooth surface: Ra=0.6

- Single rotary cutting width 20, depth 20

Processing caseⅡ

- Thread whirling machine model:XSK-6150-1000

- Worm gear M3.95

- Z1=2

- Helix angle γ=14°05′

- Length 32mm

- O.D.:39mm

- Machining time for a single part: 3 minutes

- Roughness of tooth surface: Ra=0.6

Thread Whirling Machine Application

ONMY thread whirling machine is capable of processing various kinds of threading workpieces.Worm shaft, lead screws, waveform screw, multi-screw, internal thread workpiece, spiral screw,ball screw.

Contact ONMY to Start Your Business

Have a look at how some of our clients perceive our goods and services: