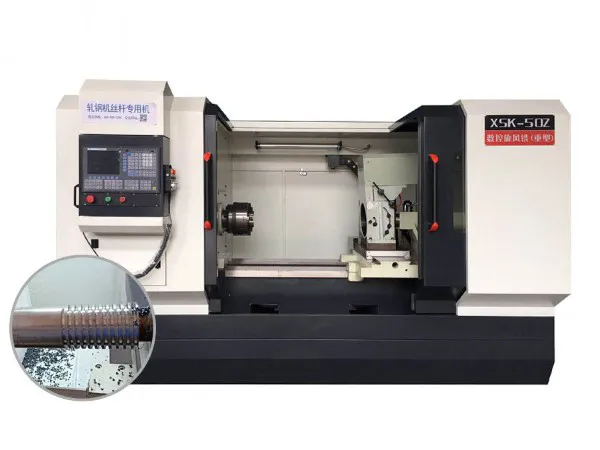

Thread whirling machine XSK-50Z

- The workpiece size support range is extensive, covering diameters from 10-300mm and lengths from 10-700mm.

- Three-axis linkage, making the processing simpler.

- Turning and milling composite processing, achieving higher processing efficiency.

- Supports both internal thread whirling and external thread whirling.

- Compared to the XSK-50, the XSK-50Z can machine workpieces with larger dimensions.

- More torque and better machine stability.

Key Features and Benefits

- Significantly improves production efficiency (with a lifespan of up to 175%).

- Machining time can be reduced by up to 50%.

- Only one machining pass is needed to achieve the highest surface quality.

- Concentricity of ±0.02mm.

- Tool disc replacement is convenient and quick.

- The length of the threads being machined is virtually unlimited.

- The depth of thread cutting (ap) can be customized.

- No rough turning required.

- No burrs are produced in the process.

Technical Specifications

| Items | Types | Parameters | |

|---|---|---|---|

| 1 | Machine body | 6150 machine body | 500*1000(mm) |

| 2 | Spindle A | Stepless gearbox | 0/25 rpm/min |

| 3 | Tailstock function | Normal | 0/110(mm) |

| 4 | X axis | Ball Screw | 2004*520 |

| 5 | Z axis | Ball Screw | 4006*2500 |

| 6 | Machine dimensions(LxWxH) | Full protection | 2840*1460*2100 |

| 7 | Thread whirling attachment | WN-20/ TC-180Q | / |

| 8 | A axis motor power | / | 130/15N |

| 9 | X axis motor power | / | 130/10N |

| 10 | Z axis motor power | / | 130/15N |

| 11 | C axis motor power | / | Class 4-3KW |

| 12 | System | / | Four-axis triplex |

| Position accuracy | / | A:0.01degree;Z-0.025;X:0.016 | |

| Repetitive positioning | / | A:0.005degree;Z:0.010;X:0.008 | |

| 13 | Max Machining Dimension | / | 10-300mm |

| 14 | Max Machining length | / | 700mm |

| 15 | Max pitch | / | Arbitrary |

| 16 | Transformer | / | 5kv |

| 17 | Jaws Chuck | 250 | 10-250(mm) |

| 18 | X axis travel | / | 200 |

| 19 | Z axis travel | / | 1000 |

Innovative Technology in Thread Whirling

- Simultaneous Multi-Axis Control: Highlight the XSK50’s ability to control multiple axes simultaneously, resulting in more precise and intricate thread patterns. This feature ensures greater accuracy and consistency in thread formation.

- High-Speed Whirling Heads: Discuss the high-speed capabilities of the XSK50’s whirling heads, which allow for faster production without compromising quality. This can include details on the rotational speed and the material compatibility.

- Precision Cutting Tools: Focus on the advanced materials and designs of the cutting tools used in the XSK50. These tools are crafted for durability and precision, reducing wear and tear and ensuring consistent performance over extended periods.

Variety of products from customer feedback

Our equipment not only produces worm gears, screws, and common fittings in industry, we can even machine oil and coal drilling equipment fittings and hooks for large cranes to perfection.

These products have been given to our company by customers from all over the world, all marvelling at the performance of our equipment. Reducing costs and increasing efficiency makes threading easier.

EPS worm shaft

Threaded pump rotor

T lead screw

8 Oil groove

Crane hook threading

Drill rod

ONMY Machines to Start Your Business

Have a look at how some of our clients perceive our goods and services:

Implementing the thread whirling machine in our production line has streamlined our entire manufacturing process. The reduction in manual labor and the machine's high-speed capabilities have drastically cut down on production times. This efficiency boost not only improves our throughput but also allows us to allocate resources more effectively. It's truly transformed our operational efficiency

James AndersonOwner

As a production manager in the automotive industry, efficiency is key. Since incorporating the thread whirling machine into our workflow, we've noticed a significant increase in production speed without sacrificing quality. The machine's ability to produce precise threads at a faster rate has not only improved our output but also reduced downtime significantly. It's an indispensable asset to our manufacturing process.

Christopher TaylorProduction manager

Previous

Next