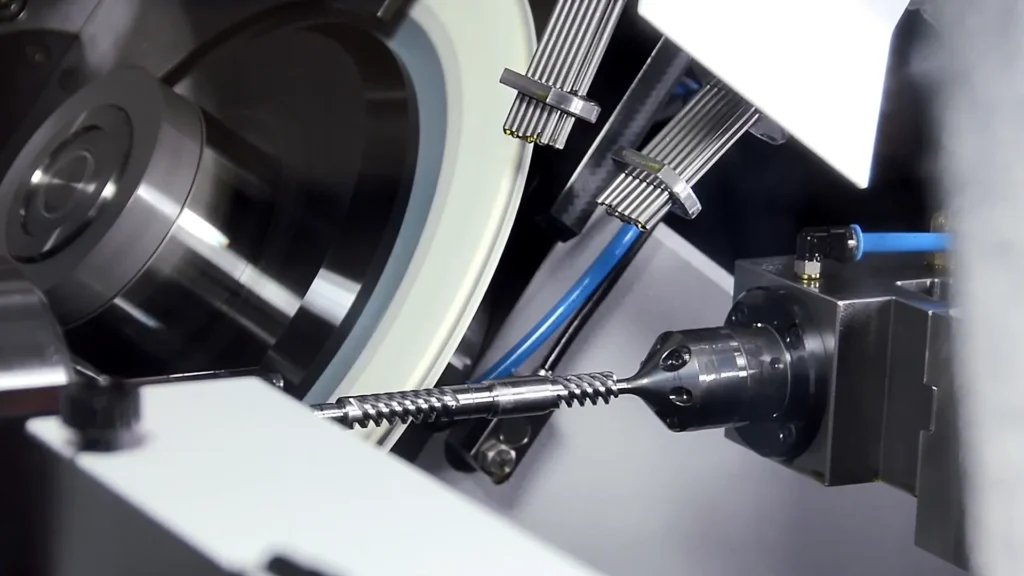

Thread grinding machine

A cnc thread grinder is a specialised machine tool for machining precision thread grinding.

It adopts the grinding method to achieve high precision and quality machining requirements by grinding threads on workpieces.

The working principle of the thread grinder is to rotate the table and grinding wheel driven by a motor, and at the same time to control the movement of the table and the feeding of the grinding wheel to realise the precise grinding of the thread.

- Grinding thread range:5mm-200mm

- Max workpiece length:450mm

- Worm gear moudles:0.5-6M

- Grinding Wheel Spindle Angle Adjustment Range: – 45° ~ 45°

- Thread leads: Any

- Grinding thread range:10mm-200mm

- Grinding gear range:10mm-350mm

- Max workpiece length:700mm

- Worm gear moudles:0.5-10M

- Grinding Wheel Spindle Angle Adjustment Range: – 45° ~ 130°

- Thread leads: Any

- Gear teeth: Any

Simple Description of Our Thread Grinding Machine

The main purpose of 7732C thread grinding machine: It is mainly used for grinding all kinds of external gears (such as straight and helical gears), cylindrical worms (such as Archimedes (ZA), normal straight profile (ZN), involute screws (ZI), etc.), trapezoidal screws and so on.

This machine tool can grind gears and worm shaft, and the spiral angle of lift can be rotated automatically from -45° to 130°.

TC-7720 CNC worm gear profile grinder adopts the latest grinding concept and novel on-line grinding wheel dressing programme, which can grind all kinds of worm gears, screws and so on.

Thread Grinding Machine Application

Thread grinding machines excel in crafting precision components with exceptionally accurate threaded forms. Their applications are widespread, including the production of ball screws essential for motion control, gears that power various machines, worm shafts for power transmission, lead screws vital for linear actuation, rolling dies that shape materials, and precise thread gauges used in quality control.

Frequently Asked Questions

What is thread grinding and how does it differ from other threading methods?

Thread grinding uses a precision grinding wheel to meticulously cut threads into a workpiece. This offers superior accuracy and surface finish compared to single-point threading or thread milling.

What are the advantages of CNC thread grinding machines?

CNC thread grinding machines offer automation, complex profile creation, superior accuracy, repeatability, and overall higher productivity.

What factors influence the accuracy of a thread grinding machine?

Machine rigidity, the accuracy of the dressing system (which shapes the grinding wheel), thermal stability, precision of the workholding system, and the quality of the grinding wheel all contribute to the accuracy achieved.

How important is the grinding wheel in the thread grinding process?

The grinding wheel is critical. Its profile, abrasive material, and how it's dressed (shaped) directly determine the thread form, accuracy, and the surface finish achieved on the part.

What are the primary applications for thread grinding machines?

Thread grinding is essential for manufacturing high-precision components like lead screws, ball screws, worms, gauges, aerospace components, medical implants, and other parts demanding critical thread tolerances.

What's the difference between external thread grinding and internal thread grinding?

External thread grinding machines shape threads on the outside of cylindrical workpieces (like screws, worm shafts), while internal thread grinding machines form threads inside bores (like nuts).

What materials can be thread ground?

A wide range of materials can be thread ground, including various steels, hardened steels, alloys, and even some ceramics.

What are some key specifications to consider when selecting a thread grinding machine?

Important specifications include maximum thread diameter, maximum thread length, number of axes controlled, spindle speed, and available options (like special dressing systems or automation features).

Contact ONMY to Start Your Business

Have a look at how some of our clients perceive our goods and services:

Inspired